ATTKTX

DELTA-ZFR™

DELTA-ZFR™

Couldn't load pickup availability

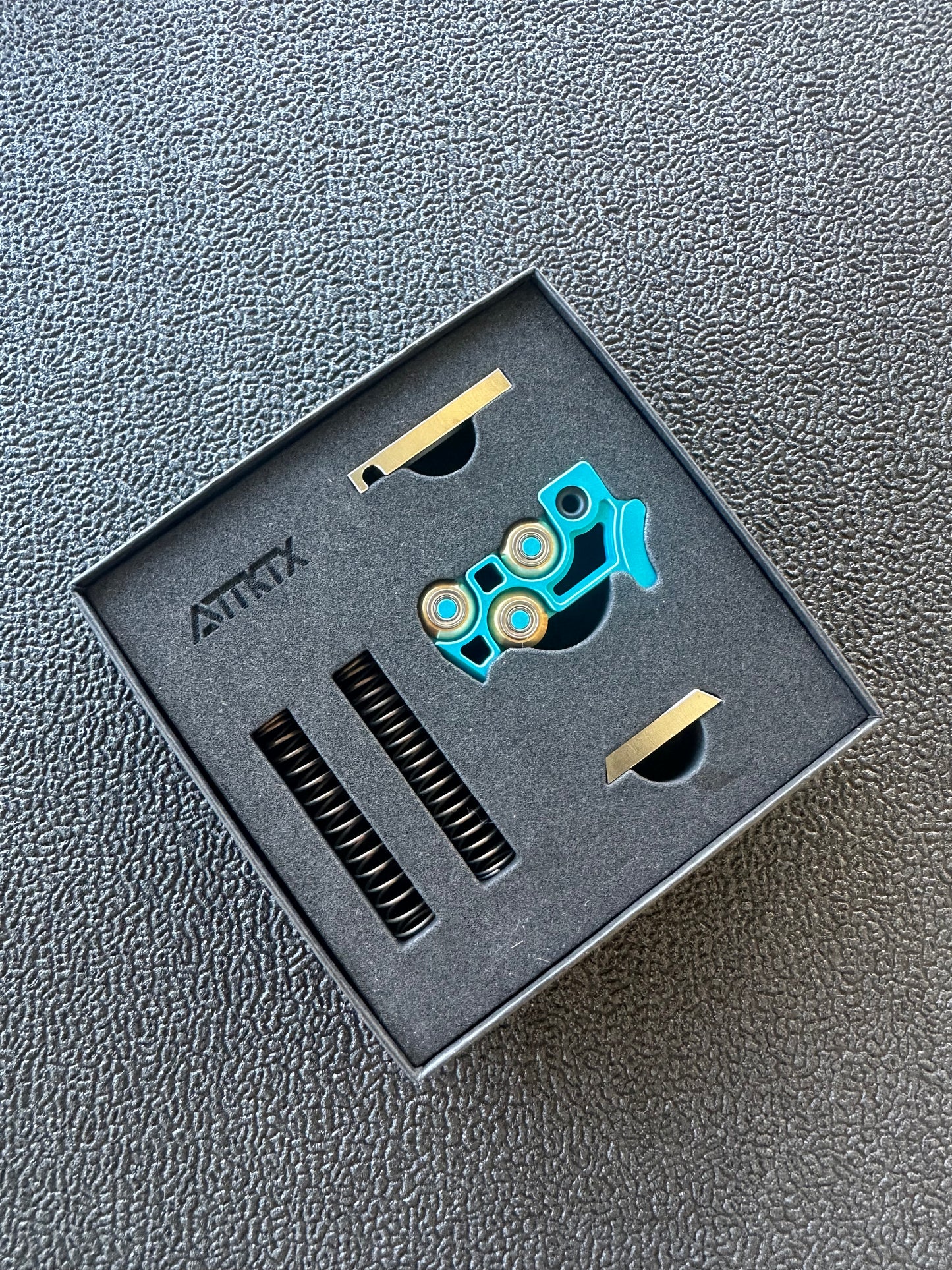

Introducing the DELTA-ZFR™ (Zero Friction Roller), a new trigger system specifically designed for the Gunfighter frame. For years, adjustable guide screws have marred the shooting experience. While crucial in fine-tuning, they often lead to unwanted drag throughout the trigger’s pull and release. ATTKTX™ set out to engineer a better solution that strategically reduced surrounding friction, while leveraging the Gunfighter's innovations. Ultimately creating a smooth, effortless pull that "glides" within the frame

TRIANGULATED DESIGN - Three-point contact bearing configuration

LARGE ROLLERS - Inspired by high-performance roller skates, creating an easy to maintain pull

SNAP-FIT | O-RING - #006 O-Ring snaps in or can be removed to fit various 3-Way actuator rod diameters

ADJUSTABILITY - Stock screws center in bottom track for vertical slack adjustment

COMPATABILITY - Compatible with Gunfighter V1 and V1.5 frames

PERFORMANCE BEARINGS - Choose between high quality ABEC-5 or Full Ceramic options

GUIDED OPERATION - 304 Stainless Steel V-Grooved tracks cradle matching V-Shaped rollers for a linear pull and release

ZERO-DRAG - CNC machined trigger features a profile thinner than the track width, ensuring drag-free side-wall operation

SELF-LUBRICATING ROLLERS - Brass rollers' lubricating properties ensure smooth operation overtime

OPTIMIZED SEAR SPRINGS - 2 Custom-Made stainless-steel springs for both light and reliable sear/trigger returns

ANGLED RAMP - 20° ramp angle over stock for faster sear activation

REDUCED WEIGHT - Ultra-machined 6061 T6 Aluminum plate cuts reciprocating mass to only 6g (11g total assembly) compared to the stock 24g

FINISH - Customize your build with Factory-Anodized Black and Clear

DISCLAIMERS:

Raw DELTA-ZFR™ triggers arrive factory tumbled and unassembled, with rollers pre-attached to bearings selected at purchase. ATTKTX™ advises using reputable anodizers for custom anodizing. Apply a small amount of high-strength thread locker (LOCTITE 648 Green) to the bearing ID for securement, ensuring no excess reaches the bearing races. Use UN-CURE™ Debonder to clean any excess thread locker.

Raw/un-anodized aluminum parts must be anodized before assembly or use, as they are not intended to provide a factory "silver-like" finish.

Factory Gunfighter frame guide screws are usually secured with high strength thread locker and may require adjustment when optimizing the DELTA-ZFR™ track system. Guide screw adjustment or removal may, but not always require the use of heat, debonders, or alternative methods. ATTKTX™ will not be held responsible for damage to components or anodizing which may occur during this process. The use of a qualified air smith or technician is recommended for installation. Guide screws should be re-secured with lower strength thread lockers upon reinstallation and final adjustment.

ATTKTX™ recommends using UN-CURE™ Debonder for guide screw removal and IC-LOC™ Thread Locker- (Blue) for guide screw reinstallation.